Your Reliable High Quality Wholesale Custom Clothing Manufacturers

T Shirt Factory Secrets: What Big Brands Don’t Tell You About Custom Printing

T shirt Factory’s secrets remain hidden from everyday consumers, even after 13 years of operation in the custom apparel industry. Most people don’t know that comes at reasonable prices without requiring massive orders.custom printing

The prices might surprise you. Youth sizes start at just $5.22, and popular brands like Gildan and Next Level are easy to find. Major t-shirt manufacturers often demand minimum orders, but T-shirt Factory offers custom printing without minimums. Small businesses and individuals can now access professional shirt production services. The production timeline runs efficiently – printed items take 3-5 working days, while embroidered products need 12 days to complete.

This piece reveals the inner workings of major shirt factories, hidden costs, material quality facts, and the industry’s actual operations. You could save up to 70% on your next custom t-shirt order with these insights.

What really happens inside a t shirt factory

A fascinating world of precision engineering and mass production exists behind the closed doors of a busy . The production line’s simplified processes emphasize both speed and scale as raw fabric transforms into finished products.

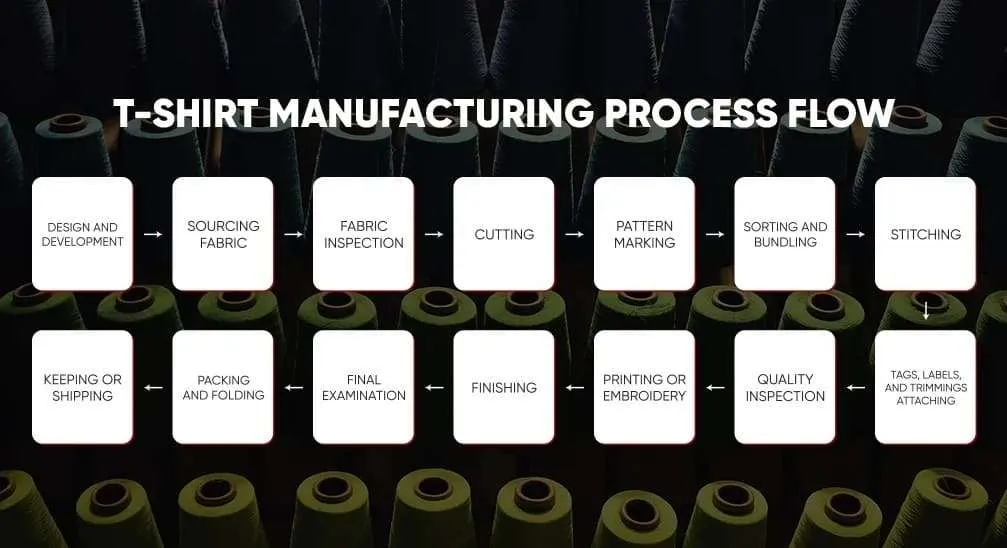

How factory t shirts are mass-produced

The production starts with massive fabric rolls that undergo systematic changes. Workers carefully stack fabric layers on cutting tables. Industrial cutting machines slice through multiple layers at once to create precise panels. These cut pieces—typically body sections, sleeves, and trim—move to sewing stations in bundles.

Each specialized machine handles a specific task in assembly. To cite an instance, one machine attaches sleeves while another focuses on hemming. The manufacturing process combines side seam stitching, sleeve attachment, shoulder seam creation, neckband application, and label insertion. Production lines at high-volume factories can make . Quality inspection and steam pressing complete the process before packaging.upwards of 50,000 t-shirts monthly

The role of automation in large-scale production

Advanced technology has revolutionized t-shirt manufacturing completely. SoftWear Automation’s “Sewbots” stand out by producing one t-shirt every 22 seconds. These machines can make up to 800,000 t-shirts daily. The robotic systems use high-speed computer vision and lightweight robotics that manipulate fabric with remarkable precision.

Modern technology now handles traditionally manual tasks:

- Robotic sewing machines that control fabric manipulation independently

- Automated fabric-cutting systems with laser technology

- Computerized pattern sewing machines that retain complex designs

- Automatic collar-attaching machines that boost hourly output beyond 100 pieces

Why big brands rely on overseas t-shirt manufacturers

China, Bangladesh, Vietnam, and India serve as manufacturing hubs for major clothing brands. This global approach exists and with good reason too. Labor costs in these regions stay low enough to make large production runs profitable. These countries’ governments provide subsidies and tax benefits to strengthen their garment industries.

These nations have developed supply chains that excel at . Chinese manufacturers’ capacity represents much of global production, with some facilities’ monthly output exceeding 400,000 garments.high-volume textile production

The hidden costs of custom printing

The sticker price rarely tells the whole story when you order . Let’s look at the expenses that many t-shirt factory businesses don’t mention upfront.custom apparel

Setup fees and minimum order quantities

Hidden setup charges can make your final bill much higher than expected. Small t-shirt manufacturers often add extra costs for screen setups, inks, handling, and packaging. You’ll pay $15-$30 for each color in your design. Single orders face charges between $20-$100.

might force you to buy more shirts than you need. Digital printers sometimes offer no minimums, but screen printing usually needs 6-12 shirts at minimum. This creates problems especially when you have a small business or just need a few custom pieces.Minimum order requirements

Color limitations and design constraints

Your design’s color count affects production costs at the shirt factory. needs separate screens for each color, which makes multi-color designs cost more.Screen printing

The printing process comes with creative limits. Most factories suggest using 1-3 colors to keep costs down. Screen printing struggles with complex elements like gradients, translucent designs, and photographs that use thousands of colors. The physical printing areas also limit how big your designs can be.

Why rush orders cost more than you think

, and the costs are a big deal as it means that customers often pay more than expected:Rush production schedules demand premium prices

- 3-day turnaround: 20% additional cost

- 2-day turnaround: 35% additional cost

- 1-day turnaround: 50% additional cost

Same-day service hits your wallet hard. Some factories charge 40% above standard pricing or a minimum of $69, whichever is greater. Even smaller rush orders cost $10-$20 extra per shirt. These high prices cover not just fast production but also disrupted manufacturing schedules, overtime pay, and quick shipping arrangements that t-shirt factories must handle.

Secrets behind design and material choices

Your t-shirt’s quality depends on its materials. These materials affect everything from comfort to durability. T-shirt factories guard their fabric production secrets closely. Material choices affect both product quality and profit margins.

Why not all cotton is created equal

Determines cotton quality. Longer fibers make smoother and more durable fabrics. Premium garments use Extra-long staple (ELS) cotton that resists pilling and keeps its shape after many washes. Regular cotton has shorter fibers with rough ends. These fibers don’t weave evenly and create coarser fabric.Fiber length (staple)

High-quality cotton feels almost silky compared to cheaper varieties. Ring-spun cotton gives superior softness. This cotton goes through continuous twisting and thinning of fibers. The process costs more because it needs more labor.

How t-shirt manufacturers cut costs on fabric

Of what it costs to make garments. Shirt factories try to save money by:Materials make up almost half

- Using shorter-staple cotton fibers that cost by a lot less than premium varieties

- Mixing different fabric types or using leftover fabrics from other runs

- Buying fabric in bulk even if it creates waste for small runs

Manufacturers often sacrifice fabric quality to keep their profits up. Factories must buy minimum quantities of fabric (usually 100 meters per roll). This drives up costs for smaller production runs.

The truth about eco-friendly claims

Today, 69% of clothes contain synthetic fibers, mostly polyester. T-shirt makers market as “green,” but these materials shed microplastics just like regular polyester.recycled polyester

Turning plastic bottles into clothing makes them end up in landfills faster since people rarely recycle clothes. “Organic cotton” claims need a closer look. While farmers grow it without synthetic pesticides, organic cotton usually comes in mid or short-staple quality. These garments often don’t last as long as premium regular cotton.

What big brands don’t want you to know

Major clothing brands hide a complex web of manufacturing relationships behind their glossy marketing campaigns. Their industry practices should change how customers see value in custom apparel.

White labeling and rebranding explained

White labeling stands as the clothing industry’s open secret. Manufacturers make similar garments that brands label as their own products. A single t-shirt factory produces the same items for several competing brands. This happens in markets of all price ranges, from budget to luxury segments. Many “exclusive” t-shirts only differ in their tags and marketing, not in their actual construction or materials.

White labeling shows why physically similar shirts can cost very different amounts based on the brand name on the label. Customers rarely find out which t-shirt manufacturer made their clothes.

How small t shirt factory often do the heavy lifting

Major clothing brands don’t make their products in-house. They give the work to smaller regional shirt factories instead. These facilities handle everything from creating patterns to packaging the final product. Brands just provide the designs and specifications.

Brands save money since they don’t need to buy manufacturing equipment. They can switch suppliers quickly if prices go up or quality drops. The actual t-shirt makers stay hidden from customers, even though they control product quality and construction.

The markup game: from factory to retail

T-shirt industry pricing shows big markups at every step:

- Per simple t-shirtFactory production cost: $3-5

- Wholesale price to brands: $7-12 (40-60% markup)

- Retail price to consumers: $20-60 (150-400% markup from wholesale)

A shirt that costs $4 to make often sells for $20-30, while premium brands charge $50 or more for similar products. Brand image, not production quality, shapes most pricing decisions. This lets major companies keep high profit margins on factory t-shirts.

Conclusion

These industry secrets will change how you look at your next t-shirt purchase. Custom printing reveals how similar shirts can have vastly different price tags just because of brand names. Big clothing companies try to hide these practices, but knowing the real production costs enables you to make better choices.

Quality differences come from fabric choices, not manufacturing techniques. Long-staple cotton offers better comfort and durability than cheaper alternatives. Notwithstanding that, many expensive shirts use the same materials as budget options because of systemic white labeling practices.

The pricing structure shows this disconnect clearly. A simple shirt that costs $4 to make can sell for $20-60 depending on the label. On top of that, it costs more for custom orders because of setup fees, minimum orders, and color limits.

Small manufacturing facilities do most of the production work without consumers knowing about them. These operations use standard processes whether they make luxury brands or budget labels.

Next time you buy custom apparel, look beyond the familiar brand names. You can get similar quality at much lower prices from factory-direct options. This knowledge about t-shirt factory secrets helps you make smarter choices and save up to 70% on your next custom order.