Your Reliable High Quality Wholesale Custom Clothing Manufacturers

How to Choose Your Perfect Private Label T-Shirt Manufacturer

The global apparel market is fiercely competitive, yet the demand for unique, high-quality t-shirts remains evergreen. For entrepreneurs and established brands looking to launch a successful t-shirt line without the immense capital and logistical burden of owning a factory, partnering with a private label t-shirt manufacturer is the most strategic path forward. This partnership allows you to focus on design, marketing, and brand building, while a trusted expert handles the complexities of production.

Choosing the right manufacturing partner is not merely a transaction; it is the foundation upon which your brand’s reputation for quality and reliability will be built. This comprehensive guide will walk you through the landscape of private label manufacturing, detail the process, and provide the critical selection criteria you need to secure the perfect partner for your 2026 launch.

Understanding the Private Label Landscape

The terms “private label” and “white label” are often used interchangeably, but they represent distinct approaches to product sourcing that significantly impact your brand’s level of customization and control. For a detailed comparison of sourcing models, you can explore the differences between White Label vs. Private Label in the apparel industry.

Private Label vs. White Label vs. Cut & Sew

| Manufacturing Model | Customization Level | Design Control | Ideal For |

| White Label | Low (Branding only) | None (Pre-existing design) | Testing markets quickly, low-cost entry. |

| Private Label | Medium to High | Full control over specs, fabric, and fit | Customizing a product line with unique branding. |

| Cut & Sew | Maximum (From scratch) | Full control over patterns and construction | High-end, complex designs, unique silhouettes. |

Private label t-shirt manufacturer services strike the perfect balance. They offer a library of existing t-shirt styles (blanks) that you can fully customize with your specific fabric blends, GSM (grams per square meter), colors, and, most importantly, your unique branding elements. This model is ideal for new and scaling brands because it significantly reduces the time and cost associated with developing a product from scratch, while still allowing for a distinct brand identity.

“Private label manufacturing means selling products under your own brand name even though you do not own the production factory. A manufacturer handles the production, and you handle the branding, marketing, and sales.” [Source: Gata Sports]

Why Private Label is Ideal for T-Shirt Brands

T-shirts are a staple product, making them perfect for the private label model. The benefits are clear:

1.Lower Minimum Order Quantities (MOQ): Since the manufacturer already has the patterns and machinery set up, they can often offer lower MOQs compared to a full cut & sew operation, making it accessible for startups.

2.Faster Time to Market: The sampling and production phases are streamlined, allowing you to launch new designs or collections much quicker.

3.Professional Quality Output: You gain immediate access to the manufacturer’s established supply chain, quality control processes, and expert labor, ensuring a professional-grade product from day one.

The Step-by-Step Process with a Private Label T-Shirt Manufacturer

The journey from a t-shirt concept to a finished product is systematic and requires close collaboration with your private label t-shirt manufacturer. For a deeper understanding of the production process, read this complete guide to private label manufacturing for new clothing brands.

From Concept to Bulk Production

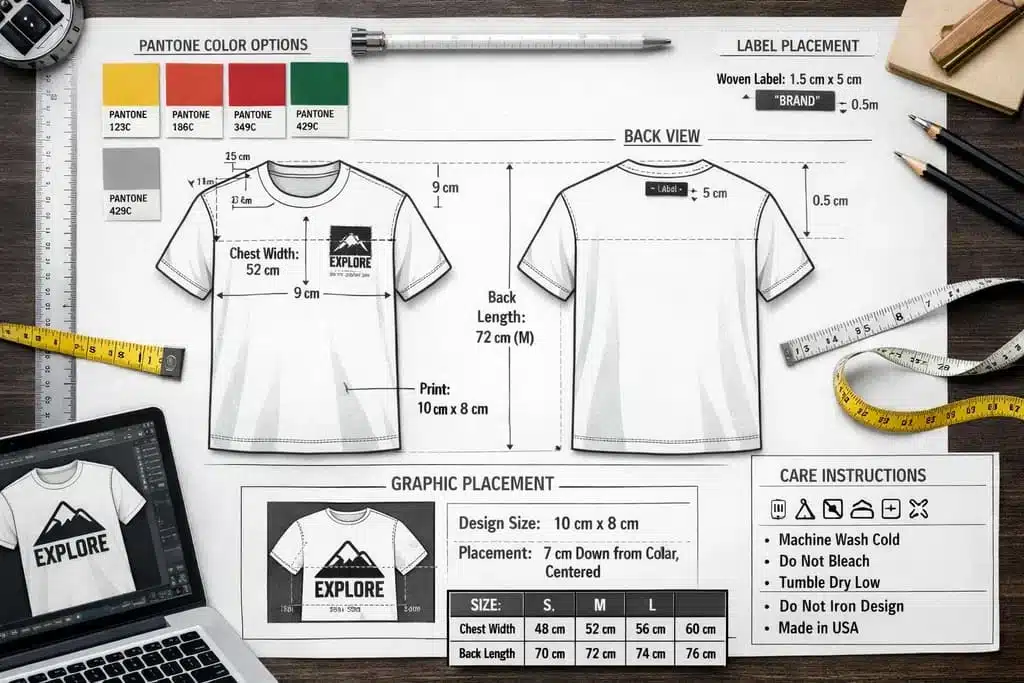

1.Product Concept and Design: You provide the manufacturer with your vision. This includes the t-shirt style (crew neck, V-neck, long sleeve), fit (slim, regular, oversized), and any graphic or print details. For a deeper dive into the creative side, check out our guide on T-Shirt Design and Mockup Best Practices.

2.Material and Specification Selection: You choose the fabric (e.g., 100% cotton, cotton/poly blend, organic), the weight (GSM), and the color. This is a critical step for determining the final feel and quality of the garment. To make an informed decision, we recommend consulting our Detailed Guide on T-Shirt Fabric Types (Cotton, Poly, Tri-Blends).

3.Branding Elements: This is where the “private label” magic happens. You provide your logo and specifications for all custom branding, including neck labels, hang tags, size labels, and packaging design. A good manufacturer will offer various options like screen printing, heat transfer, or woven labels.

4.Sample Development: The manufacturer creates a physical sample (or “proto sample”) based on your exact specifications. This phase is non-negotiable. You must meticulously review the sample for fit, fabric feel, color accuracy, and branding placement. Do not proceed to bulk production until the sample is perfect.

5.Bulk Production: Once the sample is approved, the manufacturer begins mass production. This involves fabric cutting, sewing, printing/embroidery, and final quality checks.

6.Packaging and Shipping: The finished t-shirts are individually folded, packaged according to your specifications, and prepared for shipment to your warehouse or fulfillment center.

5 Critical Factors for Selecting the Best Private Label T-Shirt Manufacturer

Your choice of private label t-shirt manufacturer will directly influence your product quality, profit margins, and brand reputation. Use these five factors to vet potential partners.

1. Minimum Order Quantity (MOQ) and Scalability

For startups, a low MOQ is essential to minimize initial investment and inventory risk. Look for manufacturers that offer MOQs between 50 and 300 units per style/color. However, also ensure they have the capacity to scale with you. A manufacturer that can handle your initial small orders and your future 10,000-unit orders is a true long-term partner.

2. Quality, Fabric Sourcing, and Sustainability

The quality of the blank t-shirt is paramount. Ask about their fabric sourcing. Do they use high-quality, ring-spun cotton? Do they offer sustainable options like organic cotton or recycled polyester? The fabric’s GSM is a key indicator of quality and durability—a heavier GSM (e.g., 180-220 GSM) often signifies a more premium t-shirt.

3. Customization and Branding Options

The ability to fully customize your branding is the core value of a private label t-shirt manufacturer. Ensure they can execute the following:

•Tag Removal/Replacement: The ability to remove the manufacturer’s tag and replace it with your custom woven or printed neck label.

•Custom Printing/Embroidery: High-quality execution of your designs, whether it’s direct-to-garment (DTG), screen printing, or embroidery.

•Custom Packaging: Options for branded poly bags, tissue paper, or hang tags to enhance the unboxing experience.

4. Communication and Transparency

Poor communication is the number one cause of manufacturing delays and errors. Choose a manufacturer who is responsive, provides clear timelines, and is transparent about their pricing and production process. They should be willing to provide references and detailed information about their quality control checks.

5. Location and Logistics

The location of your manufacturer impacts shipping costs, lead times, and ethical considerations. While overseas manufacturers (e.g., in China or Vietnam) often offer lower unit costs, a domestic private label t-shirt manufacturer (e.g., in the USA) can offer faster turnaround times and easier communication. For example, a manufacturer specializing in USA-made apparel can provide a strong selling point for customers who prioritize domestic production and higher labor standards.

Navigating Common Pitfalls and Ensuring Success

Even with the right partner, new brands often encounter avoidable mistakes. Being proactive can save you significant time and money.

The Sampling Imperative

Never skip the sampling phase. A digital mockup is not enough. You must physically inspect the sample t-shirt. Check the stitching, the fit on a real person, the color against your brand palette, and the durability of the print. Requesting a second or even a third sample is standard practice and far cheaper than correcting a mistake on a bulk order.

Negotiating Terms and Pricing

While price is important, it should not be the sole deciding factor. A manufacturer offering a price that is significantly lower than the market average is likely cutting corners on materials or labor. Focus on the Cost Per Unit (CPU), which includes the garment, printing, labeling, and packaging. Negotiate payment terms that protect you, such as a 50% deposit and 50% upon final quality inspection before shipping.

Next Steps for Your Brand

To get started on your journey, read this comprehensive guide on how to start your own clothing brand. Once you have your brand strategy locked down, you can review a list of the Top 10 Private Label Clothing Manufacturers for startups to begin your outreach.

Conclusion: Your Partner in Growth

The search for the perfect private label t-shirt manufacturer is a critical investment in your brand’s future. By prioritizing quality, transparency, and a shared vision for growth, you can transform a simple t-shirt idea into a thriving, profitable apparel line. Do your due diligence, trust the sampling process, and choose a partner who is as committed to your brand’s success as you are. For inspiration on how to turn this partnership into a successful venture, take a look at our Case Study: Launching a Successful Streetwear Brand.