Your Reliable High Quality Wholesale Custom Clothing Manufacturers

How to Choose the Right Fashion Factories: A Proven Guide for Fashion Startups

Selecting the right fashion factories can make or break your fashion startup in today’s competitive landscape. The global apparel industry is projected to reach approximately 2 trillion dollars by 2026, with the United States market alone expected to be worth $385 billion by 2025. Fashion entrepreneurs know the critical importance of finding clothing manufacturing partners who align with both your vision and production needs.

The garment manufacturing process involves several factors that deserve careful consideration. Quality, efficiency, and service undoubtedly impact your business success. The landscape becomes even more complex as consumers increasingly search for ethical, high-quality, and locally produced clothes. Modern trends like sustainable manufacturing and on-demand production are gaining popularity as buyers become more conscious about their choices. Our experience in the clothing industry shows that production timelines vary significantly based on design complexity, requiring thoughtful planning from the start.

This guide walks you through the essential steps to identify, evaluate, and partner with the right garment manufacturers for your fashion startup. From understanding manufacturing capabilities to avoiding common pitfalls, we’ve created a roadmap to help you make this crucial business decision in the fast-paced world of fashion manufacturing.

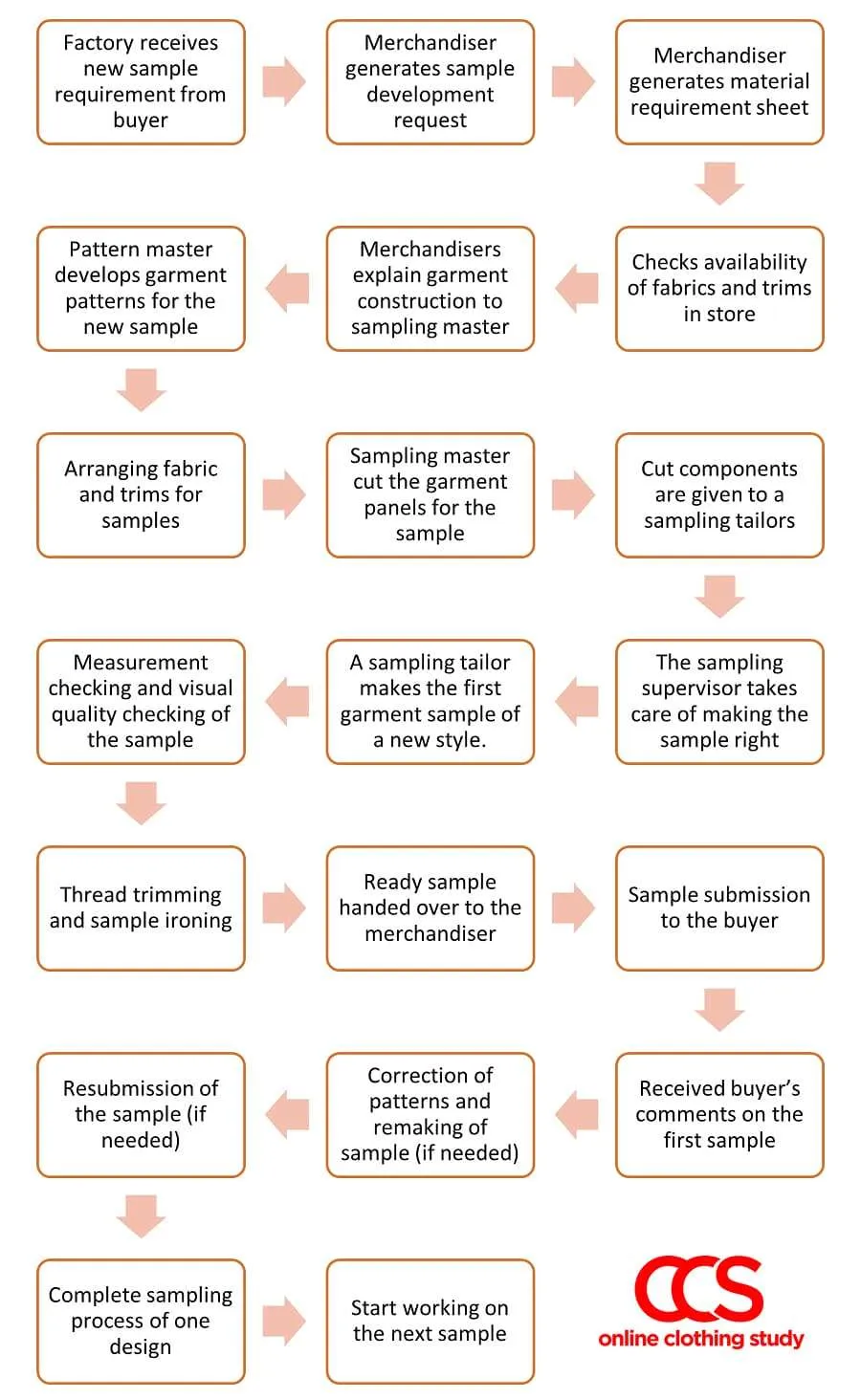

Step-by-Step Overview of the Clothing Manufacturing Process

Image Source: Online Clothing Study

Understanding the clothing production process provides crucial insight for fashion startups seeking reliable fashion garment factories. Here’s the journey from concept to finished product in the apparel manufacturing industry.

1. Design and tech pack creation

The manufacturing journey begins with transforming your creative vision into a technical blueprint. A tech pack serves as the communication tool between designers and clothing manufacturers, containing all specifications needed to produce your garment. This document includes detailed flat sketches, materials lists, measurement specs, and construction notes. A well-prepared tech pack minimizes sampling rounds and helps manufacturers provide accurate price quotations.

2. Fabric and trim sourcing

Materials acquisition comes next – a phase that directly impacts quality, cost, and production timelines. This step involves selecting and securing fabrics, buttons, zippers, labels, and other components. Consider fabric properties like washability, stretch, durability, and breathability when making selections. Verify stock availability, minimum order quantities, and lead times, as some fabrics may take 2-6 weeks to arrive or even longer for custom materials.

3. Pattern making and sampling

Pattern making translates 2D tech packs into templates for fabric cutting. These patterns determine the garment’s shape, fit, and overall structure. After creating patterns, fashion clothing factories develop samples to evaluate design, fit, and production feasibility. Common sample types include:

- Prototype samples: Initial concept verification

- Fit samples: Evaluating size and measurements

- Pre-production samples: Final approval before bulk production

4. Production planning and scheduling

Production planning aligns material availability with delivery dates while optimizing factory efficiency. The planning department fixes the Planned Cut Date (PCD) and allocates styles to sewing lines. Effective planning reduces pressure on teams and increases productivity by ensuring fabric arrives before cutting begins and production ends before scheduled delivery dates.

5. Cutting, sewing, and assembly

Once planning is complete, the physical transformation begins. Fabric is first relaxed to prevent future shrinkage, then spread, marked according to patterns, and precision-cut. Skilled textile workers stitch the pieces together following specific techniques for different garment sections. This stage requires careful attention to seam strength, stitch consistency, and construction details.

6. Quality control and packaging

Quality control occurs throughout production but intensifies as garments near completion. Inspectors check for defects, measure against specifications, and verify overall appearance. Finished garments undergo pressing, attachment of labels and tags, folding, and packaging according to brand requirements. This final step ensures products arrive market-ready and meet your quality standards.

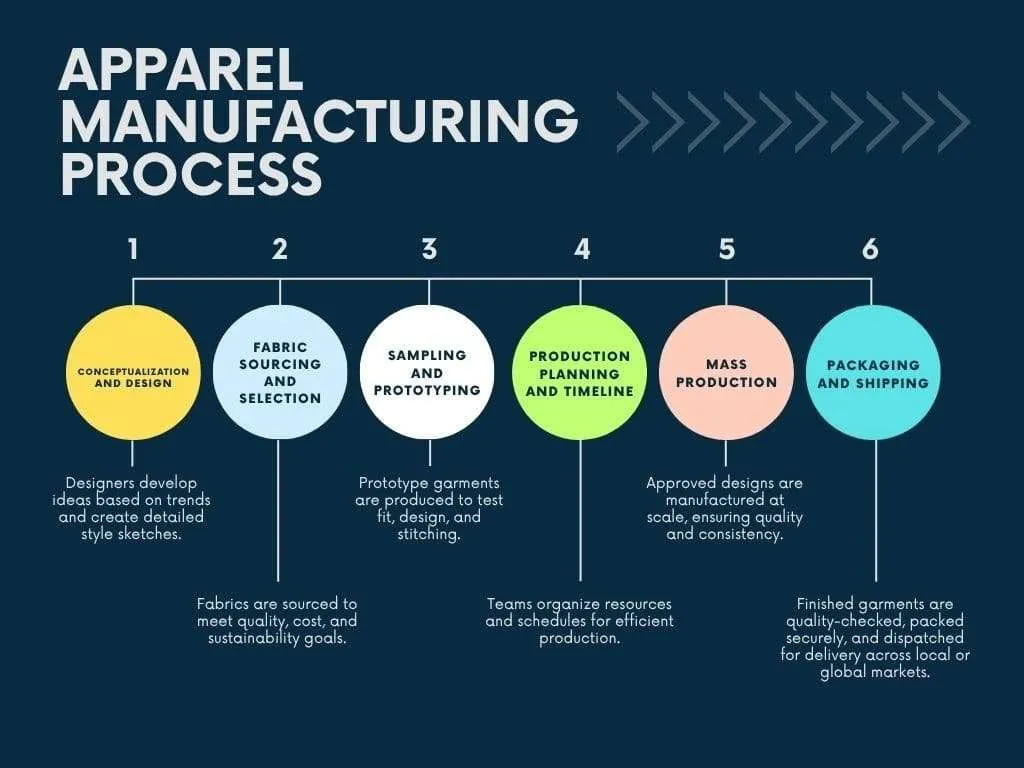

Matching Factory Capabilities with Your Startup Goals

Image Source: Pearl Global

Finding the perfect factory partnership requires aligning manufacturing capabilities with your brand’s unique vision. Moving from design to production means understanding what type of clothing manufacturer best suits your needs for success in the fashion industry.

Choosing between FPP and CMT services

Your manufacturing approach directly impacts your level of involvement, costs, and control. Cut, Make, Trim (CMT) manufacturers focus solely on constructing garments using materials you provide. This option grants greater control over fabric quality and costs while offering more flexibility for design changes. Full Package Production (FPP) handles everything from sourcing to delivery—ideal for startups needing support.

Fashion entrepreneurs with limited experience find FPP provides valuable guidance and streamlined processes. CMT might better serve established brands or those with industry connections who prefer maintaining control over their supply chain.

Understanding factory specialties (e.g., activewear, bridal)

Many garment factories produce various products, yet some specialize in specific niches. Working with manufacturers who understand your product category ensures they have the specialized equipment, knowledge, and skilled staff necessary for high-quality production.

Activewear production requires expertise in performance fabrics and technical construction methods. Bridal wear manufacturing demands meticulous attention to detailed embellishments and premium construction techniques. Selecting factories with relevant experience in your niche significantly improves product quality and reduces development challenges.

Aligning with factories that support small batch production

Most fashion startups need manufacturers with manageable minimum order quantities (MOQs). Small batch production offers several advantages:

- Lower financial risk and inventory costs

- Ability to test market response before scaling

- Flexibility to update designs frequently

- Faster production turnaround times

Some manufacturers offer minimums as low as 50 pieces per style, making production accessible for new brands. Small batch production often results in better quality control and attention to detail—perfect for premium positioning.

Evaluating potential partners means considering their production capacity and ability to scale with your growth. The right manufacturing relationship should support both your immediate needs and future expansion plans in the retail clothing industry.

Common Pitfalls Fashion Startups Should Avoid

Garment production presents potential pitfalls that can derail even the most promising fashion startups. Understanding these common mistakes will help you make informed decisions for your brand’s future in the competitive apparel manufacturing industry.

Overlooking hidden costs in the garment production process

Fashion entrepreneurs often focus solely on the base production cost without accounting for essential extras. Legal and administrative fees (USD 100-2000), shipping costs (USD 50-500 per batch), and returns management (5-10% of budget) can quickly deplete your resources. Unexpected expenses like storage costs, customs duties, and quality control can significantly impact your margins.

Choosing based on price alone

Selecting the lowest-priced fashion clothing factories seems tempting, yet this approach frequently leads to compromised quality. A lower price often signals corner-cutting in fabric quality, labor standards, or production processes. Prioritize manufacturers who deliver consistent quality, even if it means investing slightly more upfront.

Ignoring communication and responsiveness

Effective communication serves as the foundation of successful manufacturing partnerships. Poor responsiveness before production typically foreshadows missed details, production errors, and frustrating delays once work begins. Look for manufacturers who provide prompt replies, clear information, and regular updates on production status.

Failing to check for ethical labor practices

The garment manufacturing industry employs approximately 75 million factory workers worldwide, yet less than 2% earn a living wage. Overlooking ethical considerations can damage your brand’s reputation and violate consumers’ growing demand for responsible production. Verify that potential partners comply with industry standards and maintain appropriate certifications for ethical manufacturing, especially in developing countries where labor rights and workplace safety are ongoing concerns.

Tips for Building a Scalable Manufacturing Relationship

Building successful relationships with fashion garment factories begins long before mass production. The foundation you establish today determines your manufacturing partnership‘s durability and scalability as your brand grows in the fast fashion landscape.

Start with a small order to test quality

Begin your manufacturing journey with a small production run to evaluate quality standards and operational efficiency. Sample garments allow you to test quality before committing to larger orders. Initial pricing may not be ideal, but placing an order promptly demonstrates your seriousness about the partnership. After completing 2-3 orders, you’ll gain leverage to negotiate better terms.

Set clear expectations and timelines

Clear communication prevents costly misunderstandings throughout the garment manufacturing process. Establish specific requirements for materials, construction techniques, and quality standards from the outset. Develop a schedule with milestones for samples, approvals, and shipping. Timely feedback ensures early detection of potential issues, maintaining production momentum.

Use contracts to protect your interests

Formal agreements safeguard both parties in the manufacturing relationship. Your contract should clearly define scope, pricing, payment terms, quality standards, delivery schedules, and intellectual property protections. Include a non-disclosure agreement (NDA) to protect your designs—manufacturers unwilling to sign NDAs may not respect your intellectual property.

Plan for future growth and capacity needs

Consider tomorrow’s production needs alongside today’s requirements. Modular production systems provide flexibility to adjust capacity as demand fluctuates. Diversifying your supplier network ensures consistent material flow as production scales. Data-driven decision-making helps forecast trends, optimize production planning, and reduce waste—creating a sustainable growth strategy in the apparel production sector.

Conclusion

Selecting the right manufacturing partner stands as one of the most crucial decisions for any fashion startup in the clothing manufacturing industry. This guide covered essential steps that can determine your brand’s future success. From understanding the complete manufacturing process to aligning factory capabilities with your specific goals, these foundational elements require careful consideration before signing any agreements.

Successful partnerships with fashion garment factories depend on more than just production capabilities. Communication, ethical practices, and scalability matter equally when building lasting relationships. Fashion entrepreneurs should evaluate potential manufacturers through multiple lenses rather than focusing solely on price points.

Startups face challenges when entering production for the first time. Starting with small batch orders, setting clear expectations, and protecting your interests through proper contracts can significantly reduce risks. Thinking ahead about your growth trajectory helps ensure your manufacturing partnerships can evolve alongside your brand.

The perfect manufacturing partner rarely appears overnight. The process requires patience, research, and often several conversations before finding the right fit. This investment of time upfront pays dividends through smoother production cycles and consistent quality as your brand grows.

Fashion startups that approach manufacturing partnerships strategically position themselves for long-term success in the competitive apparel industry. The right garment factory becomes more than just a supplier—it becomes a critical ally in bringing your creative vision to life while supporting your business goals every step of the way.

Key Takeaways

Choosing the right garment factory is a critical decision that can make or break your fashion startup’s success in the competitive apparel market.

- Start with small batch orders to test quality and build relationships before committing to larger production runs

- Match factory specialties with your product category – activewear, bridal, or casual wear require different expertise and equipment

- Avoid choosing manufacturers based solely on price; consider communication, ethical practices, and hidden costs like shipping and duties

- Use formal contracts with NDAs to protect your designs and establish clear expectations for quality, timelines, and payment terms

- Plan for scalability by selecting partners who can grow with your brand and support both current needs and future expansion

The right manufacturing partnership extends beyond production capabilities – it requires alignment on communication standards, ethical practices, and long-term growth vision. Taking time to thoroughly evaluate potential partners upfront will save costly mistakes and create a foundation for sustainable business success in the clothing manufacturing industry.

FAQs

Q1. How do I find reliable clothing manufacturers for my fashion startup? Research manufacturers on platforms like Alibaba, request samples, and start with small orders to test quality. Look for manufacturers that specialize in your product type and can meet your minimum order quantities. Always verify their credentials and communication responsiveness before committing.

Q2. What should I consider when choosing between domestic and overseas manufacturers? Consider factors like cost, quality control, production capacity, and shipping times. Domestic fashion factories often offer faster turnaround and easier communication but may be more expensive. Overseas manufacturers can provide lower costs but may have longer lead times and potential language barriers.

Q3. How can I protect my designs when working with manufacturers? Use non-disclosure agreements (NDAs) and contracts that clearly outline intellectual property rights. Be cautious of manufacturers unwilling to sign NDAs. Additionally, consider working with manufacturers who have a track record of respecting client confidentiality.

Q4. What’s the importance of tech packs in the manufacturing process? Tech packs are crucial as they provide detailed specifications for your garment, including measurements, materials, and construction notes. A well-prepared tech pack minimizes errors, reduces sampling rounds, and helps manufacturers provide accurate price quotations.

Q5. How can I ensure ethical manufacturing practices? Research potential manufacturers’ labor practices and certifications. Look for compliance with industry standards and consider visiting the facilities if possible. Be wary of prices that seem too good to be true, as they may indicate corner-cutting in ethical practices. Prioritize transparency and open communication with your chosen manufacturer, especially regarding working conditions and fair wages for garment workers.