Your Reliable High Quality Wholesale Custom Clothing Manufacturers

Everything You Must Know About Clothing Customization with TopFit Clothing

In the modern fashion industry, customized clothing has become a significant trend. It allows consumers to express their individuality and style preferences. Advancements in technology and consumer demand for unique products drive this trend.

TopFit Clothing, one of the top clothing manufacturers in China, combines quality with tailor-made design solutions. They adhere to strict ethical manufacturing standards.

What is Clothing Customization?

Customized clothing possesses a unique quality made just for you, whether that’s a slight embellishment or an entire tailored silhouette. There are numerous ways to customize a garment. In practical terms, it can easily mean

- Customizing your clothes at home by sewing on a patch, adding some embroidery, or painting.

- Bringing in a garment to a tailor for local alteration.

- Or ordering a garment made to measure at a brand that allows you to choose your own size, fit, and even fabrication.

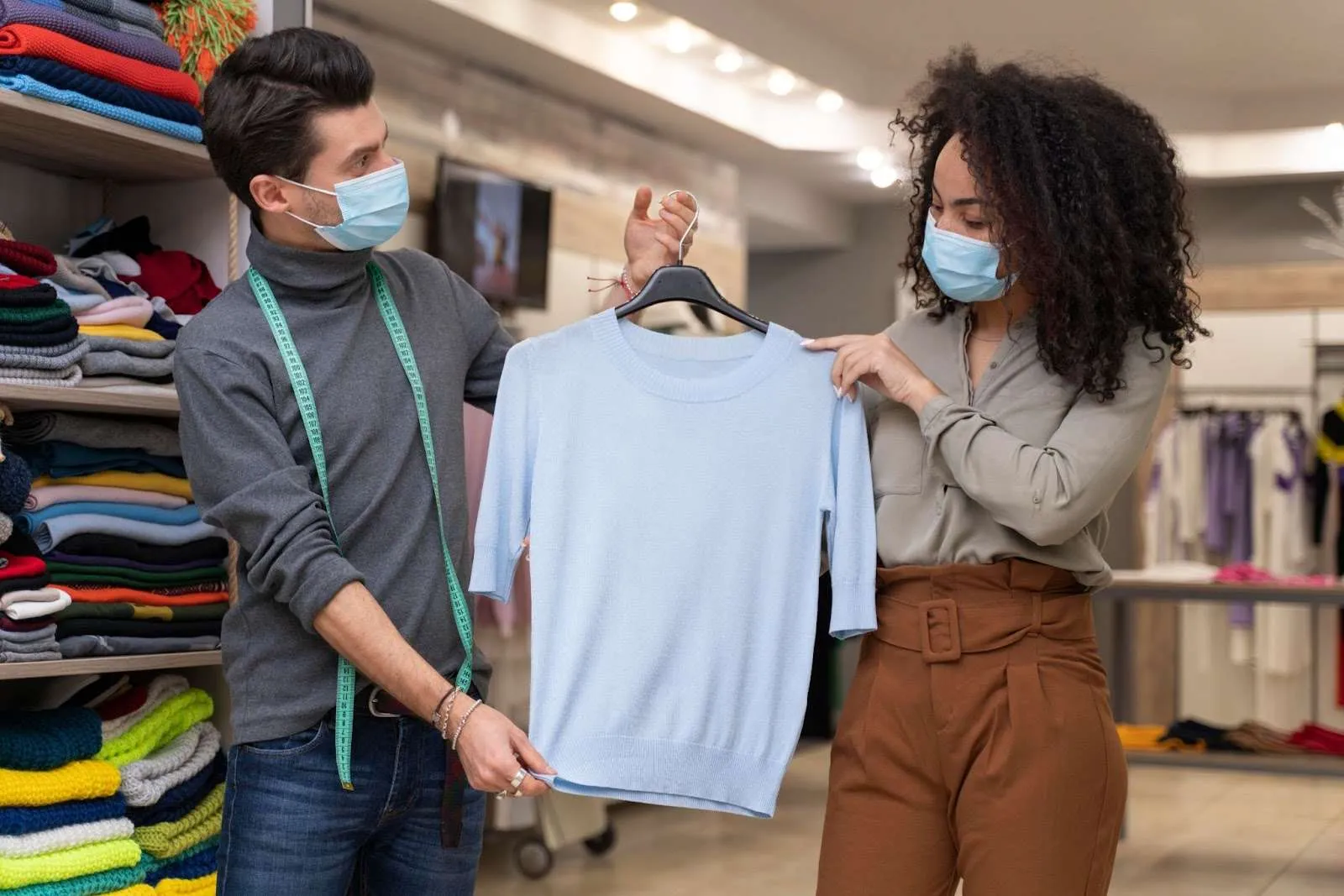

For brands and businesses that incorporate customization services into their business models, it means offering customers personalized fits and styles. These are tailored to their specific body types and style preferences. Customization may involve creating a garment from scratch, taking into account size, color, and fit. Alternatively, it may entail embellishing and reinterpreting an existing garment.

Customizations often require the active participation of a wearer, involving the process of envisioning a new design for a garment. Customizing clothes with TopFit ensures durability, comfort, and style with professional-grade techniques.

Benefits of Customized Clothing

Long-Term Investment

Customized clothing serves as both a fashion statement and a long-term investment. Custom-made outfits tend to last longer than off-the-rack items, minimizing the need for frequent purchases. This endurance translates into long-term cost savings for consumers, since they spend less replacing ill-fitting or low-quality items.

Time and Effort Savings

Shopping for customized clothing can save you time and effort. Unlike typical purchasing, where sizes may not be available, bespoke orders guarantee that the desired product is fitted to the customer’s preferences. This minimizes the frustration of discovering that a desired item has sold out or is not available in the correct size.

Customized Clothing in Business

- Brand Awareness and Loyalty: Customized clothing is an effective strategy for businesses seeking to enhance brand awareness and foster client loyalty. Branded gear acts as ongoing advertising, transforming clients into walking billboards. High-quality, tailored clothing fosters long-term relationships with customers and employees. Consequently, loyalty and retention increase.

- Cost-Effective Marketing: Customized apparel is an affordable marketing strategy. Unlike other forms of advertising, which have limited lifespans, branded clothing is worn repeatedly, providing the business with continued exposure. This type of marketing is effective and can be employed in various scenarios, such as staff uniforms and promotional giveaways.

Trends in Customized Clothing

- Sustainability and Style: In 2025, customized clothing trends will prioritize both sustainability and style. Heavyweight tees and sweatshirts remain popular due to their durability and luxury feel. Earth tones and vibrant hues provide a contemporary touch. The emphasis on eco-friendly materials and manufacturing methods reflects customers’ increased concern about environmental effects.

- Technological Advancements: Customized clothing is becoming increasingly accessible and affordable thanks to technological advancements, such as AI-powered design tools and digital printing. These improvements enable firms to create one-of-a-kind designs without incurring significant expenditures. This allows small enterprises and freelance designers to compete effectively in the market.

Step-by-Step: How to Customize Clothing with TopFit

- Requirements: Clothing design combines all design components, including color palettes, fabric textures, silhouettes, proportions, patterns, and harmony.

- Initial Costs: Costing is a method that estimates the cost of a garment based on the previously selected design, taking into account fabrics, materials, production, and logistics.

- Development: Once the design and costs have been accepted, the process moves on to pattern-making, which can be analog or digital depending on the manufacturer.

- Sourcing: Once the sample and patterns have been finalized and approved, it’s time to seek reputable suppliers who meet the specifications. During this step, manufacturers receive:

- Fabrics: Suitable suppliers are chosen based on the properties of the desired cloth, such as structure, composition, and weight.

- Materials: Refer to all of the components required for the design, excluding the cloth. This encompasses everything from threads to buttons, linings, beads, zippers, prints, and patches.

- Labels: Garments can feature a variety of labels, including size labels, care labels, flag labels, primary labels, and more.

- Cutting: Before production begins, the fabric is thoroughly inspected to eliminate any potential faults. These include weaving defects, color uniformity issues across the fabric roll, and shrinkage. All are checked before proceeding to the cutting stage.

- Manufacturing: Printing and sublimation techniques are only performed when the client and design necessitate them.

- Sewing Manufacturing: Manufacturing takes place after the cut parts are sorted by size, color (if applicable), and predetermined amounts in the cutting area. The pieces are sewn together in a linear assembly line. The garment is finished as it passes through several stations along the line. Sewing machine operators receive little stacks or bundles of cut parts and repeatedly sew the same section of the garment. They then pass the finished section on to the next operator.

- Quality Control: Outsourcing quality control is a popular trend nowadays, saving businesses the effort of physically inspecting freshly manufactured clothing. For a garment to be fully authorized, several quality control processes must be followed. This includes:

- Checking garment measures (ensuring they match the authorized sample and the client’s specifications).

- Validating that all closures, buttons, clasps, and other features work properly (malfunctions can result in bad consumer feedback or even damage). Traction, fatigue, and strain testing are among the available options.

- Checking the standards for fabric quality.

- Stitch count per inch verification is a process where a quality inspector uses a meter to determine the number of stitches per inch in a specific section of the garment.

- Confirming fabric composition. Palming the fabric can reveal variances in material composition; hence, fabric composition tests are frequently carried out.

- Finally, a final report is prepared on the quality faults and severity of the lot.

- Logistics: Refers to the process of preparing items or finished products for packing, transportation, and distribution or sale.

Following the quality check procedure, the clothing is sorted by reference, size, and color (if relevant) before being packaged in boxes. After packaging, shipment information is verified, and the package is inspected to ensure it is in good shape before being shipped to the customer.

What Should You Consider When Choosing a Custom Clothing Manufacturer?

- MOQ (minimal order quantity): The minimal quantity that a supplier agrees to sell in an order. When selecting a CCM, ensure that their minimum order quantity (MOQ) matches the company’s requirements.

- Specialization: Manufacturers typically specialize in various categories of the process. Some may specialize in swimwear, while others focus on streetwear, and so on.

- Product: When looking for a CCM, it is essential to review the items they have previously created. An excellent strategy is to request product catalogs or search for them online.

- Social Proof and Reviews: In some cases, you may be able to identify the best manufacturer without relying on external recommendations.

- Delivery timeframes: Due to delays, certain manufacturers frequently miss their delivery timeframes. Delays in the delivery of finished productions have lasted weeks, if not months.

- Technologies: Finally, another essential factor to examine is whether the potential manufacturer utilizes technologies that streamline operations, such as digital pattern making, 3D samples, and automatic cutting.

Conclusion: The Future of Fashion is Customized with TopFit Clothing

These days, in a fiercely competitive fashion arena, clothing customization has evolved from a luxury to a necessity. This is true for both brands and individuals. As we learned, custom-made clothing has its advantages, including perfect fitting, unique design, sustainable production, and budget-friendly branding.

TopFit Clothing leads the way in this revolution by combining innovative technologies with craftsmanship to provide extraordinary custom clothing solutions. If you are a business looking to build its brand or an individual expressing your design sense, our end-to-end customized clothing solutions ensure that each step guarantees quality. This applies from design consultation to final delivery.

The future of fashion is characterized by personalization, sustainability, and innovation. When you customize with TopFit, you invest in quality, identity, and longevity-profitable garments. Ready to create something extraordinary? Start your custom journey with TopFit today and know what it means to have a truly customized fashion experience.

Your vision. Our craftsmanship. Wear the difference.