Your Reliable High Quality Wholesale Custom Clothing Manufacturers

How Custom Swimwear Manufacturers Bring Your Design to Life

Quick Answer

A custom swimwear manufacturer transforms your design into finished products through a structured 10-step process. In 2026, understanding this journey is crucial for brand owners launching successful swimwear lines. According to 2026 fashion industry trends, the swimwear market demands customization, sustainability, and faster production timelines.

Why This Process Matters

Many brand owners make decisions based on incomplete information, choosing manufacturers by price alone. This leads to delays, quality issues, and communication breakdowns.

When you understand how a custom swimwear manufacturer works, you can:

•Make smarter decisions about design and materials

•Avoid costly mistakes and unrealistic timelines

•Build better relationships with your manufacturer

•Ensure products meet your quality standards

•Scale faster for future production runs

According to recent market data, brands that understand their manufacturing partners’ processes report 40% fewer quality issues and 30% faster time-to-market.

The 10-Step Manufacturing Journey

Steps 1-2: Design & Technical Drawings (3-5 weeks)

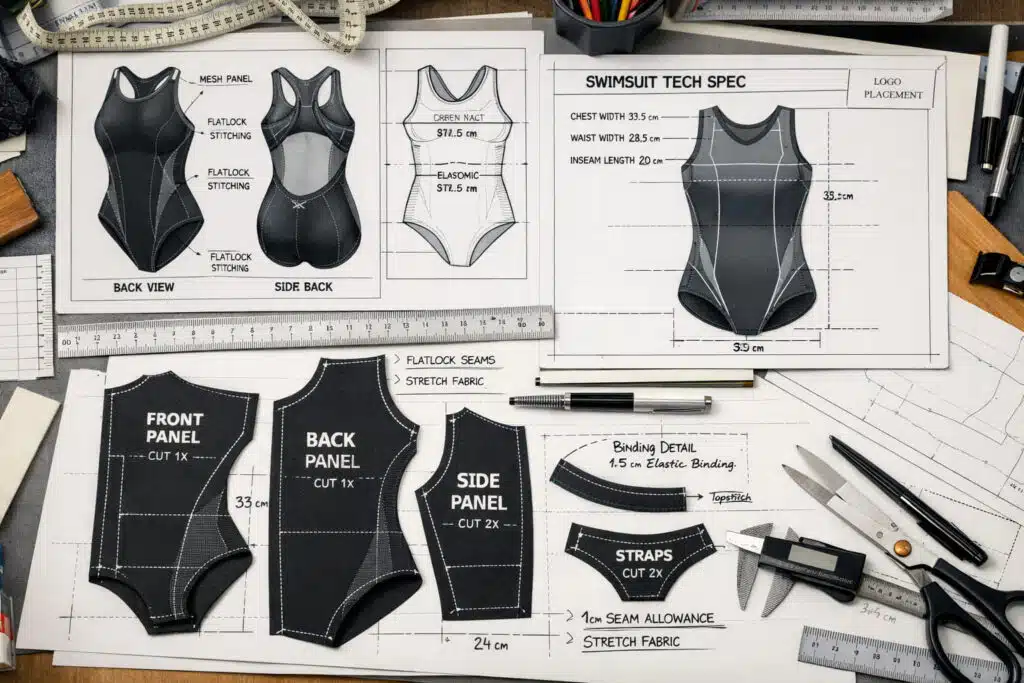

You present your swimwear idea—sketches, mood boards, or detailed drawings. The manufacturer’s design team creates precise technical drawings including pattern pieces, seam placements, and color specifications using Pantone codes.

Steps 3-4: Fabric & Color Selection (4-7 weeks)

The manufacturer presents fabric options from suppliers. For swimwear, premium choices include Italian Carvico, Econyl recycled fabric, and performance nylons. You choose colors and the manufacturer sources or dyes fabric in your exact specifications.

Step 5: Pre-Production Sample (2-3 weeks)

The manufacturer creates your first prototype. A skilled team cuts and sews using your approved drawings, fabric, and colors. This sample is inspected for fit, seam quality, color accuracy, and construction.

Great manufacturers offer sustainable options with certifications like OEKO-TEX certification for chemical safety and GRS certification for recycled materials—especially important for European retailers and environmentally conscious consumers.

Step 6: Sample Approval & Revisions (2-4 weeks)

You evaluate the sample and request changes. Good manufacturers expect revisions and handle them efficiently. This is your last chance to perfect the design before full production.

Step 7: Pattern Grading (1-2 weeks)

The approved sample is graded into all size ranges (XS-XL). A skilled pattern grader uses mathematical formulas to scale proportionally while adjusting for fit consistency across sizes.

Steps 8-10: Production, QC & Shipment (6-12 weeks)

The manufacturer schedules production and orders all materials. During production, fabric is inspected, cut using computer-controlled machines, and sewn using specialized equipment (flatlock machines for strong seams, overlock for finished edges). In-line QC inspectors check seam strength, stitch tension, color consistency, and sizing accuracy throughout.

Finally, every garment undergoes final inspection, is pressed and folded, then packed according to your specifications. Products ship by sea (15-30 days) or air (5-7 days).

What Separates Great Manufacturers

The best custom swimwear manufacturers share these qualities:

•Communication Excellence: Respond quickly, explain clearly, proactively communicate issues

•Design Expertise: Offer valuable suggestions, not just following instructions

•Quality Obsession: Multiple inspection stages, systems to catch problems early

•Flexibility: Work with various MOQs, timelines, and customization requests

•Transparency: Honest about what’s possible and realistic about timelines

•Sustainability Commitment: Offer eco-friendly processes and certifications

•Problem-Solving: Solve issues quickly instead of making excuses

Real-World Example: Wave & Grace

A startup called “Wave & Grace” wanted to launch a sustainable swimwear line targeting European retailers with a 5-month deadline and tight budget.

The Solution:

1: Design development with technical drawings

2: Fabric sourcing (Econyl recycled) and PP sample with revisions

3: Pattern grading and material procurement with OEKO-TEX and GRS certifications

4: Production with rigorous QC (0.8% defect rate)

5: Final inspection and European shipment

Result: Wave & Grace launched on schedule. Their first batch sold out in 8 weeks, and they’ve now placed three additional orders.

How to Choose the Right Manufacturer

Ask these critical questions:

1.”Walk me through your exact process from design to delivery.” Listen for clarity on quality control and communication.

2.”What’s your typical timeline for each stage?” Compare to realistic benchmarks.

3.”How do you handle design revisions?” Good manufacturers expect them.

4.”What’s your quality control process?” They should describe multiple inspection stages.

5.”Can you provide references?” Speak with 2-3 brands they’ve worked with.

6.”What certifications do you have?” Look for OEKO-TEX, GRS, BSCI.

7.”What’s your minimum order quantity?” For startups, 100-500 units is reasonable.

Your Action Plan

1.Prepare Your Design: Gather inspiration, sketches, and ideas

2.Research Manufacturers: Look for swimwear specialists with certifications

3.Request Consultations: Contact 2-3 manufacturers

4.Evaluate Their Process: Use the questions above

5.Request Quotations: Ask for detailed cost breakdowns

6.Place Your First Order: Start small to test the relationship

7.Maintain Communication: Stay in regular contact throughout production

Conclusion

The journey from your swimwear design to finished product is complex but predictable. When you understand how a custom swimwear manufacturer works, you gain a massive advantage.

You’ll make smarter decisions, avoid costly mistakes, and build products your customers love. The best brands aren’t the ones with the cheapest manufacturers—they’re the ones that understand the process and choose partners who share their commitment to quality.

If you’re ready to bring your swimwear vision to life, Topfit Clothing specializes in custom swimwear manufacturing with a focus on transparency, quality, and partnership. We’ve spent 12+ years helping over 180 brands launch successful lines. Contact us for a free consultation and let’s transform your design into a product your customers will love.