Your Reliable High Quality Wholesale Custom Clothing Manufacturers

Innovative Clothing Printing Techniques to Custom Your Designs

Introduction

The world of custom apparel production has undergone a remarkable transformation through innovative printing techniques. These advancements have revolutionized how designers bring their creative visions to life, offering unprecedented possibilities for personalization and artistic expression.

Today’s clothing printing landscape combines traditional craftsmanship with cutting-edge technology. From vibrant digital prints to smart textiles with integrated sensors, the options for customizing garments are limitless. These methods cater to different needs:

- Small-batch production for independent designers

- Mass customization capabilities for larger brands

- Sustainable printing solutions for eco-conscious creators

- High-precision techniques for intricate designs

Whether you’re a fashion entrepreneur, an established designer, or a creative enthusiast, understanding these innovative print methods can elevate your designs to new heights. Let’s explore 10 groundbreaking techniques that are reshaping the custom apparel industry and empowering designers to create unique, high-quality garments that stand out in today’s competitive market.

1. Digital Printing

Digital printing transforms your designs into wearable art through direct computer-to-garment production. This innovative technique uses specialized printers to transfer designs onto fabric with precise detail and color accuracy, making it a popular choice among customized garment manufacturers.

Key Benefits:

- Print-on-demand capability

- Minimal setup costs

- Unlimited color options

- Quick turnaround times

- Eco-friendly with reduced waste

Digital printing excels in producing intricate patterns and photorealistic images on clothing. You can create custom designs with gradient effects, subtle color variations, and fine details that traditional methods struggle to achieve. In fact, when comparing screen print and digital print, the latter often comes out on top for its versatility and precision.

Best Practices for Digital Print:

To maximize the benefits of digital printing, consider these 11 tips which cover everything from using high-resolution images (300 DPI minimum) to selecting appropriate fabric types (cotton works best). It’s also crucial to ensure proper pre-treatment of garments, maintain consistent printer calibration, and conduct test prints on sample materials.

The technique proves particularly valuable for small batch productions and personalized clothing lines. Fashion startups and independent designers leverage digital printing to test market responses without large inventory investments. For those interested in design aspects, exploring the use of spot colors in digital printing could provide further insights into achieving specific design goals; detailed information on this topic can be found here.

2. Direct-to-Garment (DTG) Printing

DTG printing technique is a game-changer for creating custom clothing. It uses advanced inkjet technology to directly spray water-based inks onto garments, resulting in precise and detailed designs that become part of the fabric.

Key Benefits of DTG:

- Unlimited color options at no extra cost

- Photorealistic detail reproduction

- Quick setup time for individual prints

- Minimal waste production

DTG is particularly well-suited for intricate designs with subtle gradients and complex color patterns. It works best on light-colored cotton garments, making it ideal for artwork, photographs, and illustrations.

Popular Applications:

- Custom t-shirt businesses

- Print-on-demand services

- Limited edition fashion collections

- Artist merchandise

- Personal gift items

The technology is especially effective for small production runs, typically ranging from 1 to 50 pieces. With DTG, you can expect consistent quality across prints as each garment receives individual attention during the printing process.

However, it’s important to note that DTG printing isn’t the only option available. There are other methods like silk-screen printing which may better suit certain needs. This article explores the benefits and techniques of both DTG and silk screen printing for custom clothing.

3. Screen Printing

Screen printing, a technique that has been a popular choice in the clothing industry for a long time, utilizes a stencil method with a mesh screen to create vibrant and long-lasting designs. This process involves pushing ink through a fine mesh screen onto the fabric, resulting in sharp and vivid prints that can withstand multiple washes.

Key Strengths:

- Unmatched durability – prints maintain vibrancy after repeated washing

- Cost-effective for bulk orders

- Creates thick, rich ink deposits perfect for bold designs

- Ideal for solid colors and spot-color designs

Limitations:

- Higher setup costs for each color

- Limited detail in photographic images

- Minimum order requirements

- Color matching challenges

Best Practices for Quality Results:

To achieve quality results in screen printing, it’s essential to follow certain best practices. Here are some key tips:

- Select mesh count based on design detail (higher count = finer detail)

- Choose appropriate ink types:

- Plastisol for cotton/poly blends

- Water-based for soft-hand feel

- Specialty inks for unique effects

- Maintain proper screen tension

- Ensure correct off-contact distance

- Use quality squeegees and consistent pressure

Screen printing is particularly well-suited for creating team uniforms, band merchandise, and promotional apparel where bold and long-lasting impressions are crucial. However, it’s important to be aware of the pros and cons of screen printing to make an informed decision.

4. Heat Transfer Printing

Heat transfer printing technique transforms your designs into wearable art through a simple yet effective process. You’ll apply heat and pressure to transfer your design from special paper onto fabric, creating lasting impressions that withstand multiple washes.

Compatible Fabrics:

- Cotton

- Polyester

- Cotton-poly blends

- Nylon

- Spandex

The versatility of heat transfer printing shines in its ability to handle:

- Full-color photographs

- Complex gradients

- Metallic finishes

- Glitter effects

- All-over prints

You can achieve professional results with minimal equipment – a heat press machine and transfer paper are your primary tools. The process works equally well for small custom orders and bulk production runs, making it a go-to choice for both hobbyists and commercial printers.

The temperature and pressure settings vary based on your fabric choice:

- Cotton: 350-375°F

- Polyester: 270-300°F

- Blends: 325-350°F

5. Dye Sublimation

Dye sublimation is a technique that turns your designs into long-lasting, vibrant prints that are seamlessly integrated into the fabric. It works by using heat to transform solid dye particles into gas, which then penetrates polyester fibers and becomes part of the material itself.

Key Features of Dye Sublimation:

- Creates design that won’t crack, peel, or fade

- Produces edge-to-edge designs with no visible borders

- Enables photographic-quality images with rich color depth

- Allows for intricate detail reproduction

Polyester fabrics are the best choice for dye sublimation printing because of their synthetic nature. When heated, the molecular structure of polyester opens up, allowing dyes to bond permanently with the fabric. This chemical reaction results in prints that stay vibrant even after multiple washes, stretching, and regular use.

Dye sublimation is particularly effective for producing:

- Athletic wear

- Custom jerseys

- Fashion accessories

- Home décor items

- Promotional products

6. Direct-to-Film (DTF) Printing

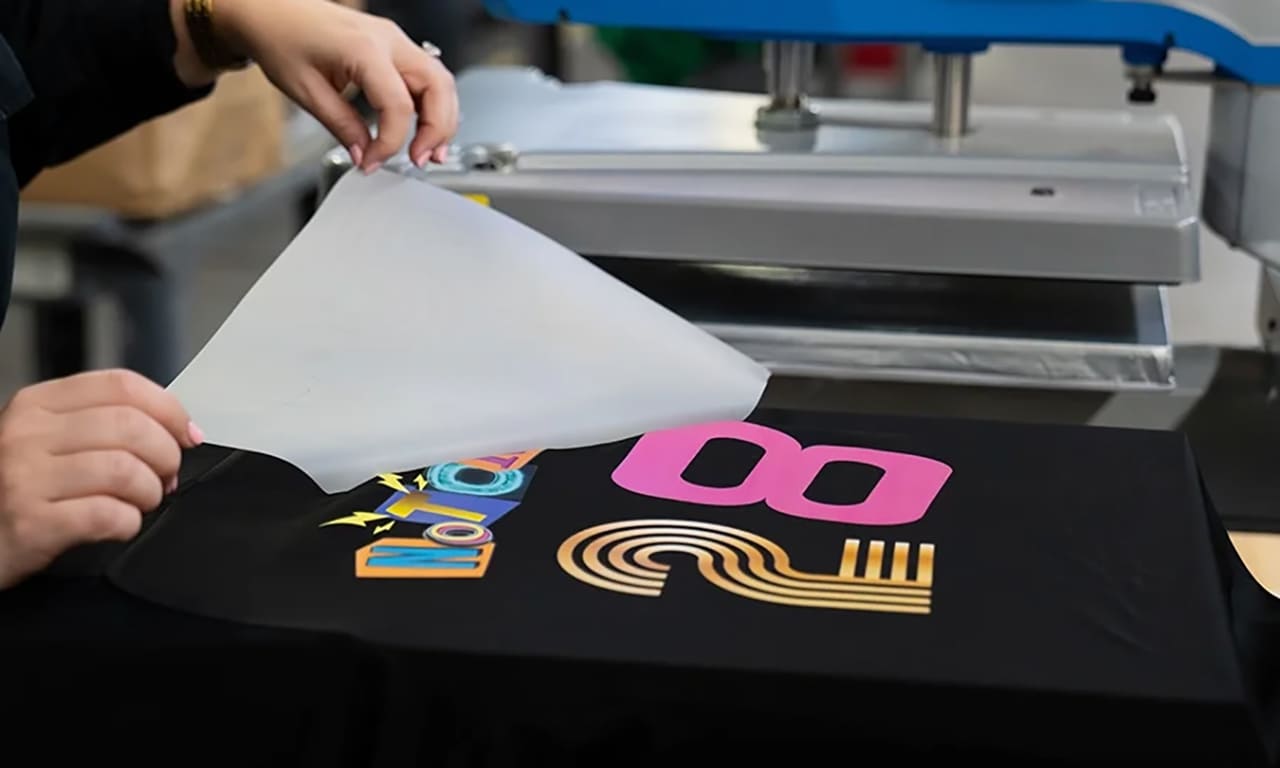

DTF printing is a game-changer for customizing garments. It uses an innovative two-step process that sets it apart from other methods.

Here’s how it works:

- Your design is printed directly onto a special PET film.

- An adhesive powder is applied on top of the print.

When heat-pressed onto fabric, this combination creates a long-lasting print that can withstand multiple washes.

Key Features of DTF Printing:

- Works on various fabric types such as cotton, polyester, and blends

- Produces vibrant, full-color designs with exceptional detail

- Creates soft, flexible prints that don’t compromise garment comfort

- Requires less setup time compared to screen printing

DTF printing stands out from DTG by eliminating the need for pre-treatment and offering superior fabric versatility. Unlike screen printing, DTF handles both small and large orders cost-effectively, making it ideal for custom designs and print-on-demand services.

You’ll achieve professional results with DTF printing across light and dark garments, thanks to its white ink capabilities and consistent color reproduction. The process excels at creating detailed designs with smooth gradients and photographic elements.

%20Printing.jpg?token=eyJhbGciOiJIUzI1NiIsInR5cCI6IkpXVCJ9.eyJ1cmwiOiJ1c2VyLWdlbmVyYXRlZC1pbWFnZXMvNDZiMTViMjEtYzJiOC00NTk2LWE0YTktNjliMTI1ZTMxNjFkL0RpcmVjdC10by1GaWxtIChEVEYpIFByaW50aW5nLmpwZyIsImlhdCI6MTc0MjUyNzU2MCwiZXhwIjoyMDU3ODg3NTYwfQ.QhwSk3pluytsS45oUtLPwjJLjIYcfGUTb5lh6Wh1Ogk)

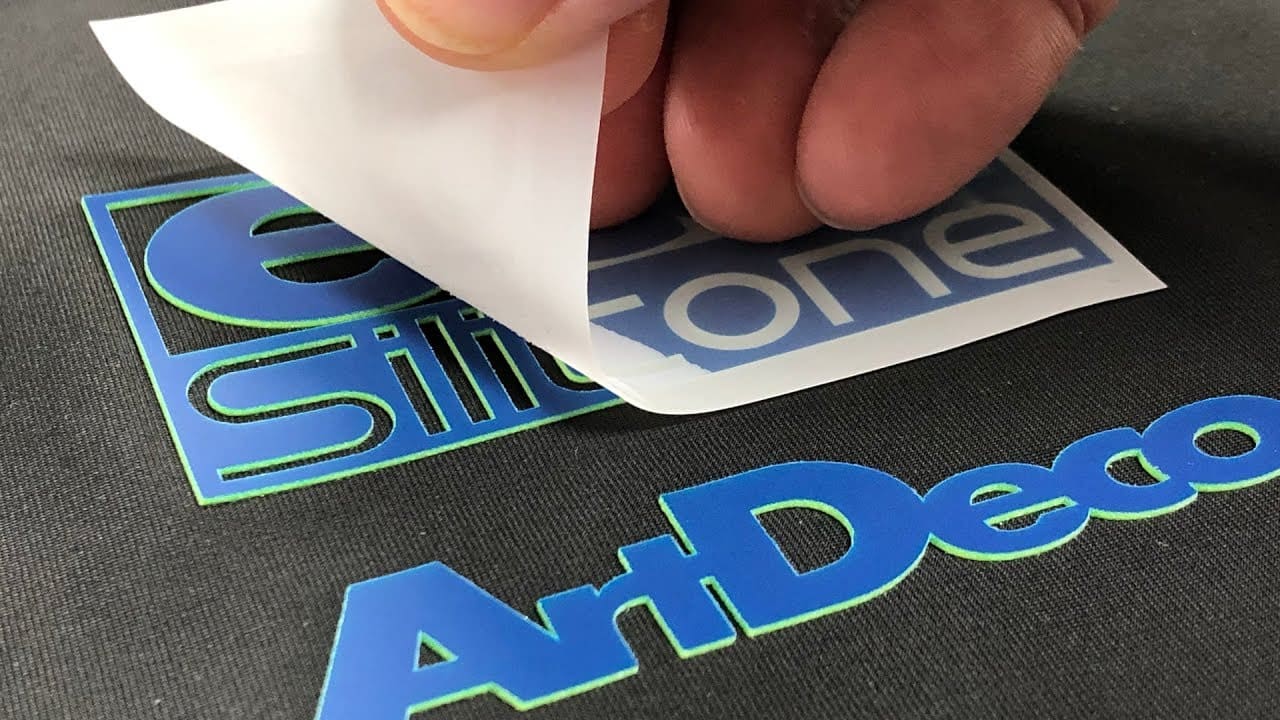

7. Plastisol Transfers

Plastisol transfers offer a unique approach to custom garment decoration through indirect screen printing. This method prints your designs onto special paper using plastisol ink, creating ready-to-apply transfers that can be stored for future use.

The process involves:

- Screen printing the design onto transfer paper

- Applying adhesive powder to the wet ink

- Drying the transfers for storage

- Heat pressing onto garments at 350-375°F

You’ll find plastisol transfers particularly effective for:

- Multi-location designs – Apply identical designs to multiple garment areas

- Bulk production – Create transfers in advance for quick application

- Consistent results – Each transfer produces identical prints

This technique delivers exceptional durability and wash resistance, with prints that maintain their vibrancy through repeated wear. The method works well on both light and dark fabrics, producing crisp, detailed designs with excellent opacity.

8. CAD Heat Transfer Vinyl Printing

CAD heat transfer vinyl printing combines digital precision with traditional heat application methods. This technique uses computer-aided design software to control cutting machines that slice intricate patterns into vinyl sheets, similar to the precision cutting techniques used in various fields.

The process works in three main steps:

- Design creation in CAD software

- Precision cutting of vinyl using specialized plotters

- Heat press application onto garments

Key Features:

- Multi-layer designs possible

- Sharp, clean edges

- Excellent durability

- Perfect for text and logos

CAD vinyl printing dominates the sports apparel industry, particularly in team uniforms and jerseys. The technology excels at producing bold, eye-catching numbers and player names that maintain their appearance through intense physical activity.

Professional sports teams value CAD vinyl printing for its:

- Consistent color reproduction

- Ability to create metallic and reflective effects

- Quick turnaround for custom jerseys

- Cost-effective small batch production

The precision cutting capabilities allow for intricate designs down to 1/4 inch, making it ideal for detailed logos and complex graphic elements on athletic wear.

9. 3D Printing in Fashion Design

3D printing is changing the game in fashion design by allowing the creation of detailed, custom-fitting clothing through a process called additive manufacturing. This innovative technology gives designers the ability to:

- Create intricate geometric designs that are impossible to make using traditional methods

- Make garments with no waste by accurately calculating the amount of material needed

- Quickly design and test prototypes before starting full production

The technology is particularly good at making:

- Bodices and corsets that are custom-fitted

- Jewelry pieces with architectural designs

- Textile structures that are unique and innovative

- Parts of garments that are seamless

Fashion brands such as Iris van Herpen showcase what 3D printing can do by crafting cutting-edge pieces that combine technology with high-end fashion. By incorporating smart materials into 3D-printed clothing, there are now new opportunities for creating garments that can respond to changes in the environment or meet specific needs of the wearer.

Recent advancements in flexible filaments have made it possible for 3D-printed clothing to be more comfortable and practical, expanding the limits of what can be achieved in fashion design. The ability of this technology to create precise patterns repeatedly while still allowing for customization makes it extremely valuable for both experimental fashion projects and everyday uses.

Smart Apparel Technologies: Merging Fashion with Functionality

Smart apparel technologies are changing the way we wear and use our clothes. These groundbreaking outfits have built-in sensors that monitor important aspects of our bodies:

- Body temperature control

- Heart rate tracking

- Analysis of movement patterns

- Detection of posture

- Measurement of muscle activity

The combination of tiny electronic components with fabric creates clothing that adapts to your requirements. Athletes can monitor their performance instantly using connected applications, while fitness enthusiasts receive immediate feedback on their posture and technique.

How Smart Apparel Works

Smart textiles respond to changes in the environment – cooling you down during intense workouts or warming you up in cold conditions. Brands like Under Armour and Nike have introduced smart clothing collections featuring moisture-wicking fabrics combined with integrated performance tracking features.

These advancements go beyond the realm of sports – medical smart garments assist patients in monitoring their recovery progress, whereas specialized professional gear improves workplace safety by detecting potential environmental hazards.

Choosing The Right Method For Your Designs And Embracing Future Trends

Selecting the perfect printing technique for your custom designs requires careful consideration of several key factors:

1. Budget and Production Scale

- Digital printing for small batches

- Screen printing for large-volume orders

- DTG for complex, detailed designs

2. Design Complexity

- Heat transfer for simple graphics

- Dye sublimation for photorealistic prints

- DTF for intricate patterns on diverse fabrics

3. Material Requirements

- Plastisol transfers for cotton-based garments

- CAD vinyl for athletic wear

- 3D printing for experimental pieces

The future of clothing customization lies in combining these techniques. Imagine merging DTG printing with smart textile technology, or integrating 3D-printed elements with traditional screen printing methods. These hybrid approaches open new possibilities for creating unique, functional designs that stand out in today’s competitive market.

Ready to bring your designs to life? Start experimenting with different techniques and push the boundaries of what’s possible in custom apparel production.