Your Reliable High Quality Wholesale Custom Clothing Manufacturers

Silk Screen Printing VS DTG Printing-Which printing methods best suits your needs?

Custom clothing has become one of the most effective ways to express creativity, promote a brand, or build team identity. Whether you’re launching a clothing line, designing event merchandise, or producing uniforms, choosing the right printing method is crucial. Among the most popular options, Silk Screen Printing and Direct-to-Garment (DTG) Printing stand out as industry favorites.

But which method best suits your needs? In this article, we’ll explore both techniques in detail, compare their advantages, and help you make an informed decision for your custom apparel projects.

Understanding the Basics of Custom Clothing Printing

Before diving into the comparison, let’s define what each printing method involves and why the choice matters.

Why Printing Method Matters

The right printing method affects:

- Print quality – how sharp, detailed, and colorful your design looks.

- Durability – how long the print lasts after multiple washes.

- Cost-effectiveness – whether the method makes sense for small batches or bulk orders.

- Fabric compatibility – how well the method works on cotton, polyester, or blends.

By understanding these factors, you can avoid costly mistakes and ensure your custom clothing reflects your vision perfectly.

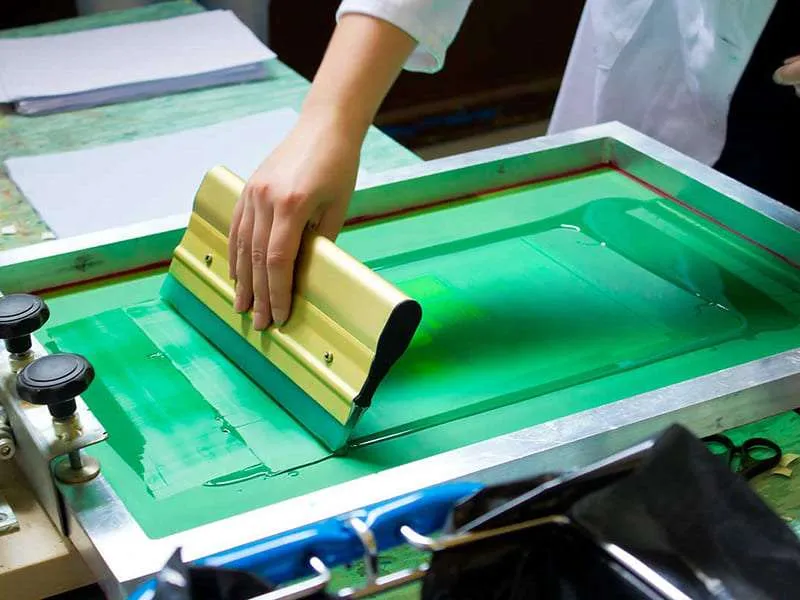

What is Silk Screen Printing?

Silk screen printing, also known simply as screen printing, is one of the oldest and most widely used printing methods in the custom clothing industry. It involves creating a stencil (or “screen”) for each color in the design. Ink is then pushed through the screen onto the fabric, layer by layer.

Advantages of Silk Screen Printing

- Cost-effective for bulk orders – Once the screens are made for printing, producing hundreds or thousands of custom clothing becomes very affordable.

- Vibrant and durable prints – The thick layers of ink result in bold colors that can withstand repeated washing.

- Versatile application – Works well on cotton, polyester, blends, and even specialty fabrics.

- Perfect for simple designs – Logos, slogans, and bold graphics shine with screen printing.

Limitations of Silk Screen Printing

- High setup costs – Preparing screens requires time and money, making small orders less economical.

- Limited color complexity – Multi-color or gradient designs require multiple screens, which increases cost and complexity.

- Not eco-friendly – The process can use more ink and chemicals compared to digital printing.

What is DTG Printing?

DTG Printing is a relatively new method that uses advanced inkjet technology to print designs directly onto the fabric. It works much like a desktop printer, except it sprays specialized water-based ink onto textiles.

Advantages of DTG Printing

- Unlimited color possibilities – Ideal for complex designs, gradients, and photo-quality artwork.

- Low setup cost – No need to create screens, making it perfect for small orders and one-off pieces.

- Soft feel – The water-based ink blends into the fabric, creating a smooth and comfortable finish.

- Fast turnaround – Great for on-demand or personalized printing.

Limitations of DTG Printing

- Less cost-effective for bulk orders – Printing each shirt individually takes more time than screen printing large batches.

- Fabric restrictions – Works best on 100% cotton garments; performance on polyester or blends can be inconsistent.

- Durability concerns – While high-quality DTG prints last well, they may fade faster than screen printing when exposed to heavy washing or rough use.

Side-by-Side Comparison: Silk Screen vs DTG Printing

To make things clearer, let’s compare the two printing methods head-to-head:

| Feature | Silk Screen Printing | DTG Printing |

|---|---|---|

| Best for | Bulk orders, bold logos, simple designs | Small batches, detailed or colorful designs |

| Print quality | Vibrant, durable, limited in detail | High-resolution, full-color, photo-like |

| Setup cost | Higher (screens required) | Minimal (no screens needed) |

| Durability | Very strong, long-lasting | Good, but may fade quicker |

| Fabric compatibility | Works on many fabrics | Best on 100% cotton |

| Turnaround time | Slower for small runs | Faster for small runs |

| Cost-effectiveness | Excellent for large runs | Better for small runs |

When Should You Choose Silk Screen Printing?

Silk screen printing is your best option if:

- You’re producing hundreds or thousands of items.

- Your design has few colors and doesn’t require photo-level detail.

- You want a durable, long-lasting finish that holds up against heavy use.

- Your project involves uniforms, promotional merchandise, or brand apparel that must withstand daily wear.

Example: A sports team ordering 500 matching jerseys would benefit from screen printing. The setup cost is spread over many garments, and the prints will stay bold and vibrant even after intense use.

When Should You Choose DTG Printing?

DTG printing is ideal if:

- You need small to medium batches or even single items.

- Your design includes gradients, photos, or fine details.

- You’re running a print-on-demand business with personalized orders.

- Comfort is important, and you want prints with a soft feel.

Example: An artist selling unique T-shirts with detailed artwork in small batches would find DTG printing more practical and cost-effective.

Combining Both Printing Methods

Interestingly, some clothing brands use both methods strategically. For instance:

- Use DTG printing for limited-edition designs or samples.

- Switch to silk screen printing when demand grows and bulk orders are needed.

This hybrid approach allows you to balance cost, quality, and flexibility while scaling your clothing brand.

Which Printing Method Best Suits Your Custom Clothing Needs?

The choice between silk screen printing and DTG printing depends on your goals:

- For large, simple, durable orders, silk screen printing is the clear winner.

- For small, detailed, colorful designs, DTG printing is unmatched.

Ultimately, both methods have their strengths, and the “best” option comes down to your budget, design complexity, and production scale.

Final Thoughts

In the world of custom clothing, no one-size-fits-all solution exists. Both silk screen printing and DTG printing can deliver amazing results when used for the right purpose. By carefully considering your design, fabric choice, and order size, you can choose the method that aligns perfectly with your needs.

If you’re still unsure, many professional clothing manufacturers and printers offer consultations to guide you toward the most cost-effective and visually stunning option.